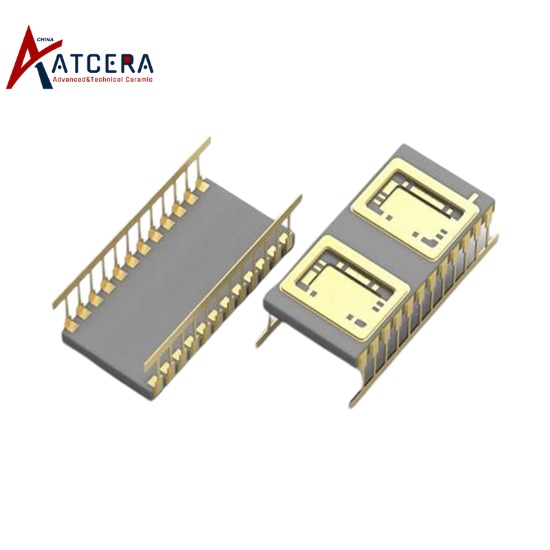

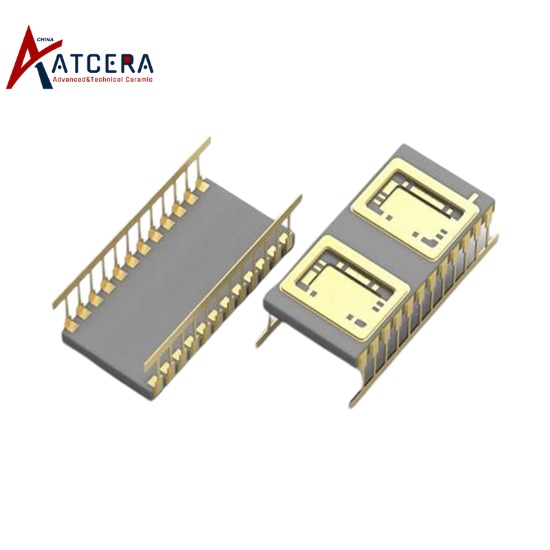

Con il rapido sviluppo della tecnologia microelettronica, i requisiti per i materiali di imballaggio elettronici sono sempre più severi. La ceramica al nitruro di alluminio, con la sua eccellente conduttività termica, eccellenti proprietà meccaniche, resistenza alla corrosione ed eccellenti proprietà elettriche, diventa il leader dei substrati di raffreddamento dei circuiti integrati e dei materiali di imballaggio su larga scala. Tuttavia, l’elevata durezza, l’elevata fragilità e la bassa tenacità alla frattura della ceramica al nitruro di alluminio rappresentano un divario insormontabile, che mette a dura prova la sua applicazione nel campo della lavorazione ultraprecisa. Soprattutto nel perseguimento di una superficie ultraliscia con rugosità superficiale Ra ≤ 8 nm o addirittura RMS < 2 nm, come ridurre efficacemente i difetti superficiali e i danni subsuperficiali durante la lavorazione è diventato un problema chiave che limita l'ampia applicazione delle ceramiche al nitruro di alluminio. In questo contesto, il processo di macinazione ELID (Electrolytic in-process Dressing) offre soluzioni innovative alle sfide di lavorazione dei substrati AlN con i suoi vantaggi unici.

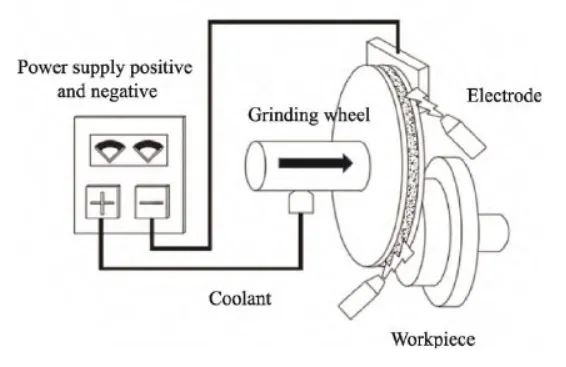

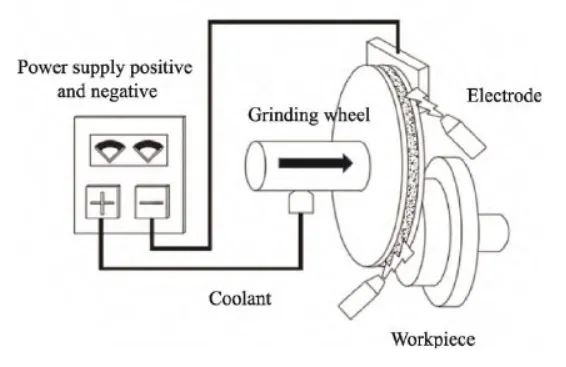

La tecnologia di rettifica ELID è una tecnologia di lavorazione di specchi compositi che integra la tradizionale rettifica, levigatura e lucidatura. Il cuore della tecnologia di rettifica ELID è realizzare un'autoaffilatura dinamica durante la rettifica attraverso la ravvivatura elettrolitica in situ delle mole, migliorando così significativamente l'efficienza della rettifica e la qualità della lavorazione. La tecnologia di macinazione ELID mostra un'eccezionale applicabilità per materiali fragili ad elevata durezza come la ceramica al nitruro di alluminio.

In primo luogo, la rettifica ELID utilizza una soluzione elettrolitica debole come fluido di rettifica, che non solo evita la potenziale corrosione del tradizionale fluido di rettifica sulla macchina utensile e sul pezzo, ma semplifica anche l'ambiente di lavorazione e riduce i costi di produzione. Ancora più importante, questa tecnologia può controllare efficacemente la temperatura durante la rettifica, riducendo le bruciature del pezzo, le tensioni residue e le crepe causate dalle alte temperature, il che è essenziale per proteggere la microstruttura e le proprietà della ceramica al nitruro di alluminio.

In secondo luogo, la rettifica ELID forma una pellicola di ossido uniforme e densa sulla superficie della mola attraverso l'elettrolisi, che non solo migliora la capacità di taglio della mola, ma migliora anche la resistenza all'usura della mola, garantendo la stabilità e la continuità della mola. il processo di macinazione. Allo stesso tempo, controllando con precisione la corrente di correzione, è possibile ottenere la regolazione precisa dello spessore dello strato di ossido e quindi ottimizzare l'effetto di rettifica, ridurre la rugosità superficiale e i danni sotto la superficie e i severi requisiti di È possibile soddisfare ceramiche al nitruro di alluminio per superfici ultra lisce.

Inoltre, la tecnologia di rettifica ELID presenta anche le caratteristiche di un processo semplice e di un funzionamento flessibile, facile da promuovere e applicare nella produzione industriale. Attraverso l'ottimizzazione continua dei parametri di macinazione e delle condizioni di processo, l'efficienza e la qualità della lavorazione delle ceramiche al nitruro di alluminio possono essere ulteriormente migliorate per soddisfare la crescente domanda di materiali ad alte prestazioni nel campo dell'imballaggio microelettronico.

In sintesi, il processo di macinazione ELID, con i suoi vantaggi unici, ha mostrato un grande potenziale nel risolvere i problemi di lavorazione causati dall'elevata durezza, dall'elevata fragilità e dalla bassa tenacità alla frattura delle ceramiche di nitruro di alluminio. Attraverso questa tecnologia, non solo è possibile ridurre efficacemente i difetti superficiali e i danni sub-superficiali nel processo di lavorazione, ma anche migliorare significativamente l'efficienza e la qualità della lavorazione, il che costituisce una solida base per l'ampia applicazione della ceramica al nitruro di alluminio nel campo della imballaggio elettronico. In futuro, con il continuo sviluppo e miglioramento della tecnologia di rettifica ELID, si ritiene che le sue prospettive di applicazione nel campo della lavorazione ultraprecisa saranno più ampie e contribuiranno al continuo progresso della tecnologia microelettronica.