Nel dinamico mondo dell’elettronica avanzata, la chiave per restare all’avanguardia risiede nella continua ricerca dell’innovazione. Poiché la tecnologia continua ad evolversi a un ritmo rapido, i substrati semiconduttori Si3N4 ad alte prestazioni stanno emergendo come i pionieri nella rivoluzione del settore. Con la loro eccezionale stabilità termica, resistenza meccanica e proprietà di isolamento elettrico, i substrati Si3N4 stanno liberando la vera potenza dell'elettronica avanzata come mai prima d'ora.

Incorporando substrati Si3N4 nei dispositivi elettronici, i produttori sono in grado di ampliare i limiti delle prestazioni e dell'efficienza. Questi substrati migliorano le capacità di gestione della potenza dei componenti elettronici, consentendo velocità di trasmissione dei dati più elevate, una migliore gestione termica e una maggiore affidabilità. Che si tratti di smartphone, elettronica automobilistica o applicazioni aerospaziali, i substrati Si3N4 stanno trasformando il modo in cui sperimentiamo la tecnologia.

Poiché la domanda di dispositivi elettronici veloci, affidabili ed efficienti dal punto di vista energetico continua a crescere, i substrati semiconduttori Si3N4 sono pronti a guidare il settore nel futuro. La loro combinazione unica di resistenza e proprietà isolanti li rende un ingrediente essenziale nello sviluppo di dispositivi elettronici all'avanguardia.

Quindi, allacciatevi le cinture e preparatevi a esplorare le possibilità illimitate offerte dai substrati semiconduttori Si3N4. Il futuro dell’elettronica avanzata inizia da qui.

Vantaggi dei substrati semiconduttori Si3N4

I substrati semiconduttori in nitruro di silicio (Si3N4) sono emersi come un punto di svolta nel mondo dell'elettronica avanzata, offrendo una moltitudine di vantaggi che stanno rivoluzionando il settore. Uno dei principali vantaggi dei substrati Si3N4 è la loro eccezionale stabilità termica. A differenza dei tradizionali materiali semiconduttori, Si3N4 può resistere alle alte temperature senza comprometterne l'integrità strutturale o le proprietà elettriche. Questa resilienza termica è fondamentale nelle applicazioni in cui i componenti elettronici sono soggetti a calore intenso, come nell'elettronica di potenza, nei dispositivi ad alta frequenza e nell'elettronica automobilistica.

Un altro vantaggio chiave dei substrati Si3N4 è la loro eccezionale resistenza meccanica. Questi substrati sono rinomati per la loro capacità di resistere a livelli elevati di stress e deformazione, rendendoli la scelta ideale per applicazioni in cui durata e affidabilità sono della massima importanza. Questa resistenza meccanica si traduce anche in una migliore dissipazione del calore, poiché i substrati possono trasferire efficacemente il calore lontano dai componenti elettronici sensibili, migliorando le prestazioni complessive e la longevità del sistema.

Furthermore, Si3N4 semiconductor substrates possess excellent electrical insulation properties, which is a critical factor in the design and fabrication of high-performance electronic devices. These substrates effectively isolate electrical signals, preventing cross-talk and ensuring signal integrity, which is essential for applications such as radio frequency (RF) and high-speed digital circuits. This insulating property also contributes to the improved power handling capabilities of Si3N4-based electronic devices, enabling them to operate at higher voltages and power levels without compromising reliability.

Applications of Si3N4 semiconductor substrates in advanced electronics

The exceptional properties of Si3N4 semiconductor substrates have made them an indispensable component in a wide range of advanced electronic applications. In the realm of power electronics, Si3N4 substrates are widely used in the manufacture of high-power transistors, inverters, and motor drives. These substrates provide the necessary thermal management and electrical insulation, allowing power electronic devices to operate at higher voltages and switching frequencies, resulting in improved efficiency and reliability.

In the automotive industry, Si3N4 semiconductor substrates have become increasingly prevalent, particularly in the design of electronic control units (ECUs) and other safety-critical components. The robust mechanical properties and thermal stability of these substrates ensure that automotive electronics can withstand the harsh environmental conditions encountered in vehicles, such as extreme temperatures, vibrations, and shocks. This, in turn, enhances the overall reliability and safety of modern automobiles.

The aerospace and defense sectors have also embraced the use of Si3N4 semiconductor substrates, as these applications often demand the highest levels of performance and reliability. In these industries, Si3N4 substrates are utilized in a variety of electronic systems, including radar, avionics, and satellite communications. The unique combination of thermal, mechanical, and electrical properties offered by Si3N4 substrates enables the development of advanced electronic systems that can operate reliably in the demanding environments encountered in aerospace and defense applications.

The future of Si3N4 semiconductor substrates in the electronics industry

As the demand for faster, more efficient, and more reliable electronic devices continues to grow, the role of Si3N4 semiconductor substrates in shaping the future of the electronics industry cannot be overstated. With the ever-increasing complexity and power requirements of modern electronic systems, the exceptional properties of Si3N4 substrates make them an increasingly attractive choice for manufacturers and designers.

Looking ahead, the integration of Si3N4 semiconductor substrates into a wide range of electronic devices is expected to accelerate. From next-generation smartphones and wearables to cutting-edge industrial automation and renewable energy systems, Si3N4 substrates will play a crucial role in enabling the development of high-performance, energy-efficient, and reliable electronic components.

Furthermore, the ongoing research and development in the field of Si3N4 substrate manufacturing processes are expected to drive further advancements in the technology. Improvements in material quality, manufacturing techniques, and cost-effectiveness will likely lead to the widespread adoption of Si3N4 substrates across the electronics industry, solidifying their position as the preferred choice for a wide range of applications.

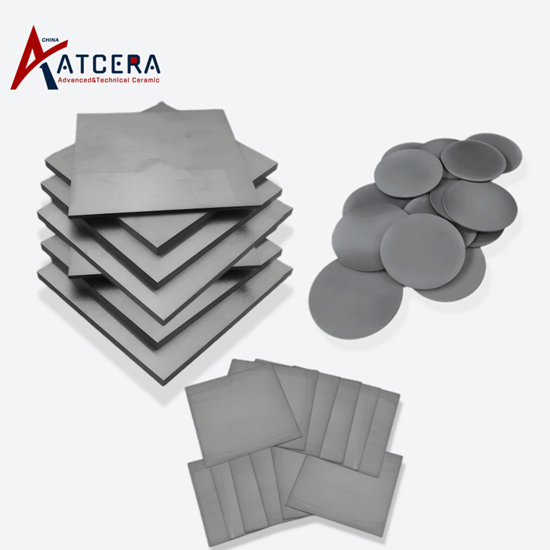

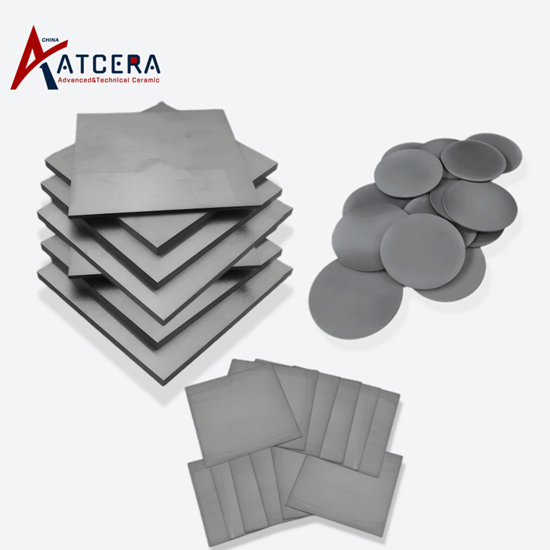

Manufacturing process of Si3N4 semiconductor substrates

The manufacturing of high-quality Si3N4 semiconductor substrates involves a complex and meticulous process that requires precise control over various parameters. The production of Si3N4 substrates typically begins with the synthesis of the raw material, silicon nitride, through a chemical reaction between silicon and nitrogen.

One of the most common methods for producing Si3N4 is the chemical vapor deposition (CVD) process, where silicon and nitrogen-containing precursor gases are introduced into a reaction chamber and subjected to high temperatures. This process allows for the controlled deposition of a thin, uniform layer of Si3N4 on a suitable substrate, such as silicon or sapphire.

Following the Si3N4 deposition, the substrate undergoes a series of precision machining and polishing steps to ensure a smooth, defect-free surface. This surface preparation is crucial, as it directly impacts the performance and reliability of the electronic devices that will be fabricated on the substrate.

To further enhance the properties of the Si3N4 substrate, various post-processing techniques may be employed, such as thermal annealing or the application of protective coatings. These additional steps help to optimize the substrate's thermal, mechanical, and electrical characteristics, making it better suited for specific electronic applications.

The manufacturing of Si3N4 semiconductor substrates requires a high level of expertise, advanced equipment, and stringent quality control measures to ensure the production of consistently reliable and high-performing materials. As the demand for these substrates continues to grow, manufacturers are continuously innovating and improving their processes to meet the ever-evolving needs of the electronics industry.

Key properties and characteristics of Si3N4 semiconductor substrates

The exceptional properties and characteristics of Si3N4 semiconductor substrates are what make them so valuable in the world of advanced electronics. One of the most notable features of Si3N4 is its exceptional thermal stability, which allows it to withstand high temperatures without compromising its structural integrity or electrical performance. This thermal resilience is particularly crucial in power electronics and high-power applications, where the substrate must be able to effectively dissipate heat generated by the electronic components.

In addition to its thermal stability, Si3N4 is renowned for its exceptional mechanical strength and hardness. These properties contribute to the substrate's ability to withstand high levels of stress and strain, making it an ideal choice for applications where durability and reliability are paramount, such as in automotive electronics and aerospace systems.

Another key characteristic of Si3N4 semiconductor substrates is their excellent electrical insulation properties. These substrates are highly effective at isolating electrical signals, preventing cross-talk and ensuring signal integrity, which is essential for high-frequency and high-speed digital circuits. This insulating capability also allows Si3N4-based electronic devices to operate at higher voltages and power levels without compromising reliability.

Furthermore, Si3N4 substrates exhibit a low coefficient of thermal expansion, which closely matches that of the semiconductor materials commonly used in electronic devices. This thermal compatibility helps to minimize the risk of thermal-induced stresses and failures, contributing to the overall reliability and performance of the electronic systems.

The combination of these exceptional properties – thermal stability, mechanical strength, electrical insulation, and thermal compatibility – makes Si3N4 semiconductor substrates a highly sought-after material in the electronics industry, enabling the development of cutting-edge electronic devices that are more powerful, efficient, and reliable than ever before.

Challenges and limitations of Si3N4 semiconductor substrates

While Si3N4 semiconductor substrates offer numerous advantages, they are not without their challenges and limitations. One of the primary challenges in the widespread adoption of Si3N4 substrates is the relatively higher cost compared to traditional semiconductor materials, such as silicon or gallium arsenide.

The manufacturing process of Si3N4 substrates is complex and requires specialized equipment, as well as a high level of expertise and quality control measures. This, in turn, can drive up the overall production costs, making Si3N4 substrates less accessible for some manufacturers, especially in price-sensitive markets.

Another limitation of Si3N4 substrates is their relatively lower thermal conductivity compared to some other semiconductor materials, such as silicon carbide (SiC) or diamond. While Si3N4 substrates exhibit excellent thermal stability, their ability to dissipate heat may be slightly less efficient in certain high-power applications, where the thermal management requirements are particularly demanding.

Additionally, the manufacturing of large-diameter Si3N4 substrates can be more challenging and may result in higher defect rates, limiting the availability of large-scale wafers for high-volume production. This can be a constraint for manufacturers who require larger substrate sizes to meet their specific design and production needs.

Despite these challenges, the electronics industry is continuously working to address the limitations of Si3N4 substrates through ongoing research and development.

Advancements in manufacturing processes, material engineering, and cost-reduction strategies are expected to help overcome these obstacles and further drive the adoption of Si3N4 substrates in the future.

Comparison of Si3N4 semiconductor substrates with other semiconductor materials

When it comes to semiconductor substrates, Si3N4 stands out as a unique and highly capable material, offering a combination of properties that are often unmatched by other semiconductor materials. One of the primary advantages of Si3N4 over traditional silicon (Si) substrates is its superior thermal stability and mechanical strength.

While silicon is a widely used semiconductor material, it can be susceptible to thermal degradation and mechanical failures at high temperatures or under high-stress conditions. In contrast, Si3N4 substrates can withstand much higher temperatures and exhibit greater resistance to mechanical stress, making them a better choice for power electronics, high-frequency, and harsh-environment applications.

Another semiconductor material that has gained significant attention in recent years is silicon carbide (SiC). Like Si3N4, SiC also offers excellent thermal stability and mechanical strength, making it a viable alternative for advanced electronic applications. However, Si3N4 substrates generally have a lower coefficient of thermal expansion, which can be advantageous in terms of thermal compatibility with semiconductor devices and reduced thermal-induced stresses.

Gallium nitride (GaN) is another semiconductor material that has seen increasing adoption in high-power and high-frequency electronics. While GaN-based devices can offer excellent performance, they often require specialized substrate materials, such as sapphire or SiC, to support their unique properties. In this context, Si3N4 substrates can serve as a cost-effective and compatible alternative, providing a suitable platform for the integration of GaN-based components.

In terms of electrical insulation properties, Si3N4 substrates outperform many other semiconductor materials, including silicon and gallium arsenide (GaAs). This superior insulation capability allows Si3N4-based electronic devices to operate at higher voltages and switching frequencies, improving overall efficiency and performance.

Overall, the unique combination of thermal, mechanical, and electrical characteristics of Si3N4 semiconductor substrates makes them a highly versatile and attractive choice for a wide range of advanced electronic applications, where the demand for high-performance, reliable, and efficient devices continues to grow.

Importance of high-performance Si3N4 semiconductor substrates in the development of advanced electronics

The role of high-performance Si3N4 semiconductor substrates in the development of advanced electronics cannot be overstated. As the electronics industry continues to push the boundaries of performance, efficiency, and reliability, these exceptional substrates have become an essential component in the quest for technological breakthroughs.

One of the key drivers behind the importance of Si3N4 substrates is the growing demand for power-dense and energy-efficient electronic devices. In industries such as automotive, aerospace, and renewable energy, the ability to handle high power levels while maintaining thermal stability and reliability is crucial. Si3N4 substrates, with their exceptional thermal management capabilities and mechanical strength, enable the design and manufacture of electronic components that can operate reliably under these demanding conditions.

Furthermore, the insulating properties of Si3N4 substrates are crucial in the development of high-frequency and high-speed electronic devices, such as those used in telecommunications, radar systems, and advanced computing. By effectively isolating electrical signals and preventing cross-talk, Si3N4 substrates help to ensure the integrity and performance of these mission-critical electronic systems.

As the world becomes increasingly reliant on advanced electronics, the need for reliable, durable, and efficient devices has never been more pressing. Si3N4 semiconductor substrates play a pivotal role in meeting these demands, enabling the creation of innovative electronic products that are better equipped to handle the challenges of the modern world.

From smartphones and wearables to industrial automation and renewable energy systems, the integration of high-performance Si3N4 substrates is transforming the electronics industry, paving the way for a future where advanced electronics are more powerful, efficient, and reliable than ever before.

Conclusion: The potential and outlook of Si3N4 semiconductor substrates in the electronics industry

Poiché l’industria elettronica continua ad evolversi a un ritmo rapido, il ruolo dei substrati semiconduttori Si3N4 nel plasmare il futuro dell’elettronica avanzata è diventato sempre più evidente. Questi materiali eccezionali, con la loro impareggiabile stabilità termica, resistenza meccanica e proprietà di isolamento elettrico, sono pronti a svolgere un ruolo fondamentale nello sviluppo di dispositivi elettronici all’avanguardia che sono più potenti, efficienti e affidabili che mai.

Il potenziale dei substrati Si3N4 è vasto, poiché possono essere perfettamente integrati in un'ampia gamma di applicazioni elettroniche, dall'elettronica di potenza e dai dispositivi ad alta frequenza ai sistemi automobilistici e aerospaziali. Poiché la domanda di componenti elettronici veloci, affidabili ed efficienti dal punto di vista energetico continua a crescere, i substrati Si3N4 rimarranno in prima linea nell’innovazione tecnologica, consentendo ai produttori di oltrepassare i limiti di ciò che è possibile.

Guardando al futuro, il futuro dei substrati semiconduttori Si3N4 nel settore elettronico è pieno di promesse. Si prevede che i continui sforzi di ricerca e sviluppo porteranno a ulteriori progressi nella qualità dei materiali, nei processi di produzione e nell’efficienza dei costi, portando infine all’adozione diffusa di questi substrati in tutto il settore.

Poiché il panorama dell'elettronica continua ad evolversi, la versatilità e le prestazioni dei substrati Si3N4 li renderanno un componente sempre più indispensabile nella ricerca di dispositivi elettronici all'avanguardia e ad alte prestazioni. Dagli eleganti smartphone che abbiamo in tasca ai sistemi avionici avanzati dei nostri aerei, l’impatto dei substrati Si3N4 si farà sentire in un’ampia gamma di settori, plasmando il futuro della tecnologia come la conosciamo.

In conclusione, il potenziale dei substrati semiconduttori Si3N4 nell’industria elettronica è davvero illimitato. Poiché la domanda di dispositivi elettronici più veloci, più efficienti e più affidabili continua a crescere, questi materiali eccezionali svolgeranno senza dubbio un ruolo fondamentale nell’inaugurare una nuova era di elettronica avanzata, trasformando il modo in cui interagiamo e sperimentiamo il mondo che ci circonda.